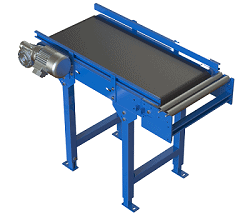

Product Overview

| Drive Type | Centre drive unit |

|---|---|

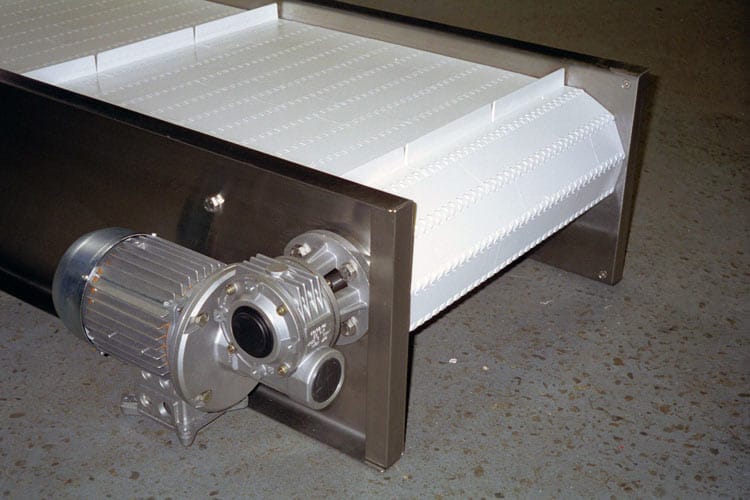

| Drive power options (kW) | 0.75 kW braked motor |

| Frame Material | Mild steel or Stainless steel |

| Frame Finish | Mild Steel = Powder coated Stainless Steel = Self colour |

| Frame Detail | Bed depth options = 140mm & 142mm |

| Idle Roller Diameter Options | 115mm |

| Drive Roller Diameter Options | 160mm rubber lagged |

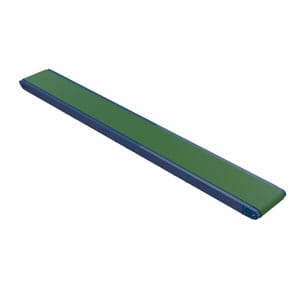

| Belt material options | Grip top & longitudinal belt |

| Max floor height | Bespoke, choose your height |

| Standard degree of incline | 20 degree, 25 degree & 28 degree |

| Standard belt width options | 450mm, 600mm, 750mm,800mm, 900mm & 1000mm |

| Series options / accessories | Inclined conveyor Terminal nose over option 1,000mm nose over option 1,000mm horizontal infeed option Safety pop out rollers Various speed options Variable speed control Bespoke electrical control panels Stop, start & emergency stop buttons Photo electric cells & bar code reading, Side guides Can be joined by other conveyors to make system Underguarded as standard |

| Useful Information | Above is just to give an overview of the standard range, we can manufacture bespoke to suit your requirements. |

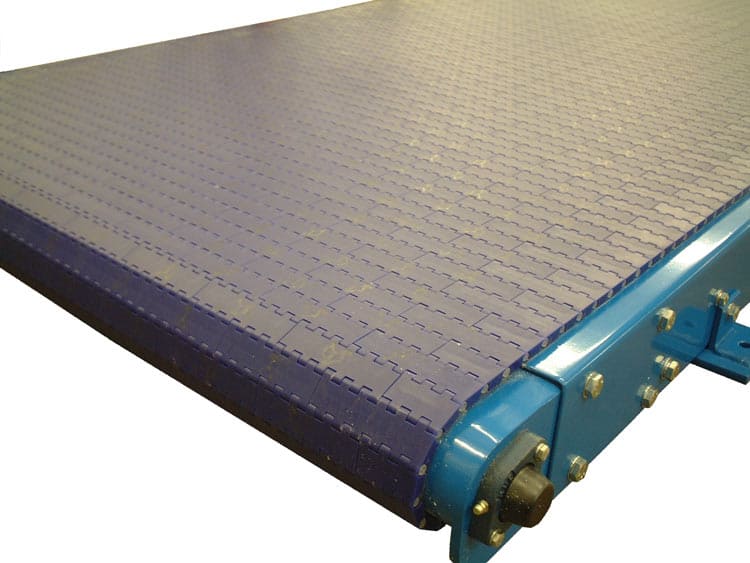

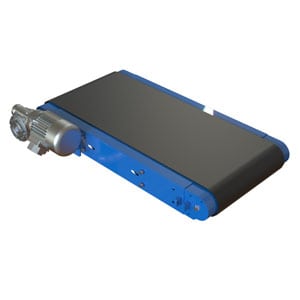

Used in many arduous environments from sub zero conditions up to temperatures over 100 degrees Celsius. They are especially useful for heavy side loading or off loading along its length. The direct sprocket drive ensures no tracking problems, whatever the belt width or length.

It also eliminates any belt slippage and because it allows the belt to run loose dramatically reduces load on the drive shaft bearings.

This in turn reduces power requirements. With the all round low friction properties of these conveyors the outstanding feature must be long life expectancy with minimal maintenance.

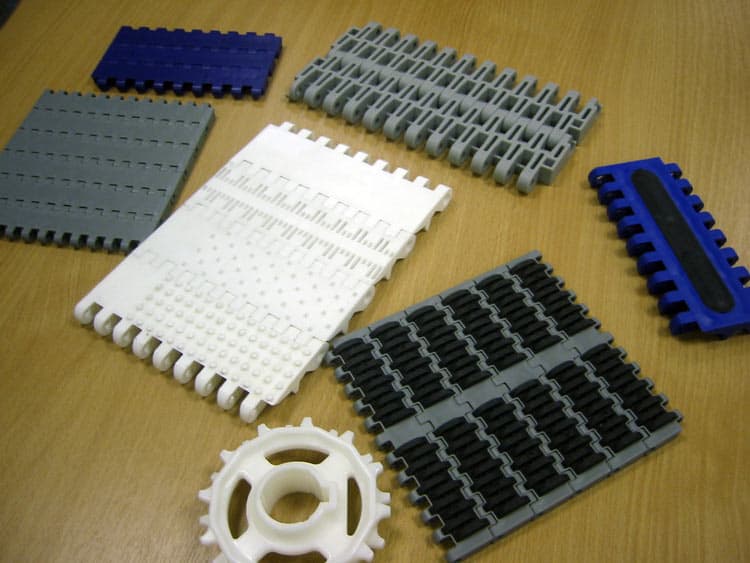

- Belts are available in many different profiles and materials to suit almost every application.

- Positive direct sprocket drive ensures no tracking problems.

- Robust heavy duty belt types resistant to cuts and hot products.

- Available in many belt configurations, flat-top, perforated, slotted, flighted and grip top.

- Damaged belts can easily have individual slats replaced.

- These machines can be constructed with either mild steel or stainless steel framework. Mild steel is perfect for most post and parcel applications & stainless steel is ideally suited to the food industry where washdown situations are a regular requirement.

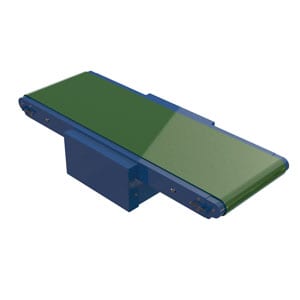

- These belts are even available with rollers in to achieve product accumulation.

- Standard material types: Polypropylene (PP) for use in many general applications. Polyethylene (PE), another lightweight thermoplastic, is characterized by superior fatigue resistance, high impact strength, and flexibility. Acetal (PA) thermoplastics are considerably stronger than PP and PE. Acetal features a good balance of mechanical, thermal, and chemical properties and a low coefficient of friction