Product Overview

Ocon conveyors offer various types of package and tote handling powered roller conveyor to suit many customers conveyor applications.

Line-shaft powered roller accumulation conveyor:

Lineshaft accumulation conveyor drives rollers via elasadrive bands from a drive spool, in turn these are driven by an under-slung drive shaft powered by an AC 240/415volt motor gearbox. The friction between the spool and the shaft drives the roller.

This type of roller conveyor offers accumulation properties once the line pressure exceeds the drive. Various modular ancillary accessories are available to assist in mechanically controlling the product.

24volt DC – “ZLP” Zero line pressure powered conveyor:

This type of powered roller conveyor has a positive drive. Slave rollers are driven by linked drive belts to form a drive zone. Each zone section is powered by a centrally mounted 24volt DC motor and represents a product a zone which is controlled via intelligent drive cards. These cards allow plug and play configurations and have preprogramed logic options. Purpose conveyor roller sensors are used to detect the product.

Belt under roller Zero Line Pressure “ZLP” powered roller conveyor:

Belt-under roller drives precision gravity rollers by a belt running under the rollers. A pneumatically operated rack pushes the belt to the underside of the rollers to drive the product. As upstream accumulation of product is detected the rack releases turning the conveyor back into a gravity conveyor. This obviously has ideal zero-line pressure accumulation properties. Once the accumulated product up stream restarts a signal is sent to lift the pneumatic racks to drive the rollers once again.

Accessories & Features

Many standard ancillary modules and accessories are available for all powered roller ranges.

- Tapered roller bends, 30, 45, 60 and 90 degree.

- Roller merge and mitre sections.

- Pneumatic operated high-speed wheel sorters and roller switches.

- Pneumatically operated line-brake pads, stops, pushers and turn devices.

- 90 degree chain transfers and belt transfers.

- Personnel access gates.

- Standard parcel and pack positioning units.

- Pneumatically operated line-brake pads, stops, pushers and turn devices.

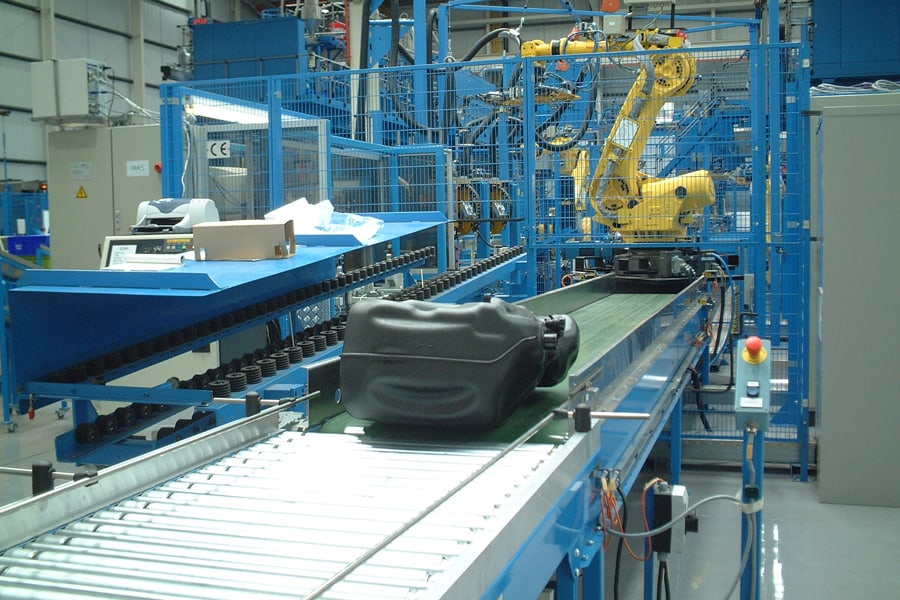

Heavy duty chain to chain pallet handling powered roller conveyor:

Chain driven powered roller conveyor is often used to transport heavy pallets or heavy products with a flat firm base. Products without a firm base can be placed on a purpose made slave boards or jigs. The conveyor is of a heavy robust construction with 80mm diameter rollers at 150mm pitch. This type of conveyor drives has direct chain drive properties, powered by an underslung AC drive motor centrally mounted. Standard widths available to accommodate an 800 x 1200mm long pallet or 1000mm x 1200mm long pallet. Ancillary modules include: chain transfers and turntables.